L and U Channel#

Using L and U Channel in your designs

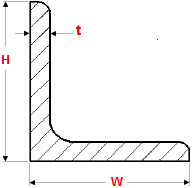

L Channel also known as Angle Iron#

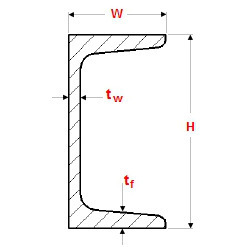

U Channel#

Overview#

- L Channel is commonly used for brackets

- U Channel is commonly used when all of the sides of square, or rectangle tubing is not required, because its lighter

- U Channel can also be used as a slider guide, becuase of its case like structure

- FRC teams typically use 6061 aluminum L and U Channel on their robots

See table of contents for a breakdown of this section.

Info#

- L and U Channel is typically sold in long lengths of stock that you cut to size

- L Channel is typically measured by Outside Width, Outside Height, Wall Thickness, and stock length

- U Channel is typically measured by Width, Height, Leg Thickness, Base Thickness, and stock length

- The Width and Height will vary based on the application of the material

- Widths and Heights are typically the same in L Channel, but only sometimes in U Channel

- L Channel widths and lengths 3255 uses are typically (1" x 1"), (1.5" x 1.5")", and (2" x 2")

- U Channels widths and lengths 3255 uses are typically (1" x 1")", (2" x 1"), and (2" x 2")

- Thicker walls lead to stronger parts, but also heavier ones

- Wall thicknesses are most commonly 1/16", 1/8" and 1/4"

L and U Channel Fabrication#

- L and U Channel can be cut to length by Horizontal Bandsaws, or Chopsaws

- Lightweighting is not commonly done on L and U Channel